Management and disposal of poultry litter are two of the greatest challenges that poultry producers face. Improper litter management can result in serious flock health and welfare issues and can lead to odors, fly breeding, and excess nutrients in soil and water resources. Commercial broiler litter is commonly recycled for several flocks before an entire clean-out is performed and new bedding material placed on the broiler house floor.

In some regions (Mississippi and Delmarva, for example), it may have been 10 years or more since many broiler houses were totally cleaned out. A portion of litter may be removed when the litter gets too deep (more than 6 inches), but enough is left to leave at least 3 inches on the floor, and this litter is leveled back out for future flocks. Removal and replacement of broiler litter varies widely across the poultry industry and can range from two flocks to many years of production (Chamblee and Todd, 2002; Malone, 1992; Tabler et al., 2015).

Litter Production and Nutrient Content

Litter exists in two forms:

- caked litter (typically greater than 35 percent moisture), often found under and near drinkers and near evaporative cooling pads

- loose litter

Caked litter is commonly removed from the house after each flock is harvested. The remaining loose litter is reused multiple times to grow future flocks of birds. This results in production of two types of waste materials with potentially different characteristics and nutrient content (Coufal et al., 2006). The Natural Resource, Agriculture, and Engineering Service (NRAES, 1999) reported whole litter production from broilers to be 1.25 tons per 1,000 birds, with cake production at 0.4 tons per 1,000 birds. Thus, according to NRAES (1999), cake represented 30–35 percent of the total litter. Depending on clean-out frequency, Malone et al. (1992) reported that cake accounted for 35–40 percent of total litter production. Tabler (2000) found cake was 28 percent of total litter production on a commercial broiler farm in Arkansas. In experimental pens, Coufal et al. (2006) found cake as a percentage of all litter produced per flock averaged 39.8 percent on an as-is basis.

While the fertilizer value of litter is well recognized, nutrient content of litter can be extremely variable (VanDevender et al., 2000). Litter nutrient content and the rate of litter production can be affected by numerous factors, including the number of flocks grown on the same litter material, initial type and amount of bedding material used, type of housing, litter management practices, feed formulation, flock health, ventilation rate, drinker management (height and water pressure), performance parameters, stocking density, and flock age at harvest (Malone, 1992). As a result, estimates of litter production and nutrient content vary greatly.

Litter production rates are most commonly reported as tons of litter on an as-is basis per 1,000 broilers. Patterson et al. (1998) reported different rates of litter production from two companies growing birds to different body weights in commercial broiler houses in Pennsylvania. Farms growing smaller birds produced litter at a rate of 1.07 tons per 1,000 birds, and farms growing larger birds produced litter at a rate of 1.65 tons per 1,000 birds. On a commercial broiler farm in Arkansas, Tabler (1999) found that smaller birds produced litter at a rate of 1.11 tons per 1,000 birds (unpublished data). Malone (1992) estimated average broiler litter production rate to be 1.0 dry metric tons per 1,000 broilers per flock, with a range of 0.7 to 2.0. Chamblee and Todd (2002) estimated broiler litter production from broilers in Mississippi to be 1.6 tons per 1,000 birds if houses were cleaned out annually, and 1.0 ton per 1,000 birds if houses were cleaned out completely at the end of 2 years.

Variation in Nutrient Content and Production

There is a wide range of variation regarding litter nutrient content in the literature. Tabler and Berry (2003) followed nine flocks of broilers on the same litter at a commercial broiler farm in Arkansas and found nitrogen (N) increased from 33.8 (1.69 percent) to 60.3 (3.02 percent) pounds per ton, phosphorus (P2O5) increased from 42.5 (2.13 percent) to 69.3 (3.47 percent) pounds per ton, and potassium (K2O) increased from 36.6 (1.83 percent) to 58.3 (2.92 percent) pounds per ton on an as-is basis (Table 1). Litter moisture ranged from a low of 22.3 percent (Flock 9; August 1996) to a high of 26.0 percent (Flock 5; February 1996). Berry (1997) reported the 4-year average N, P2O5, and K2O content of litter from an Arkansas commercial broiler farm cleaned out completely on an annual basis was 57.3 (2.87 percent), 64.9 (3.25 percent), and 50.0 (2.50 percent) pounds per ton, respectively, on an as-is basis (Table 2). Moisture content of the litter over the 4-year period ranged from 23.09 to 28.13 percent.

Malone (1992) reported an average (as-is basis) of 2.94, 3.22, and 2.03 percent for N, P2O5, and K2O, respectively, from several U.S. sources. Chamblee and Todd (2002) reported Mississippi broiler litter contained 2.85, 1.45, and 2.95 percent N, P2O5, and K2O, respectively. Patterson et al. (1998) reported broiler litter in Pennsylvania to have an average N, P2O5, and K2O content of 3.73, 3.11, and 2.18 percent, respectively. Sharpley et al. (2009) reported N, P2O5, K2O, and water-extractable phosphorus (WEP) levels of 62 (3.10 percent), 68.7 (3.44 percent), 62.4 (3.12 percent), and 1.9 pounds per ton, respectively (Table 3).

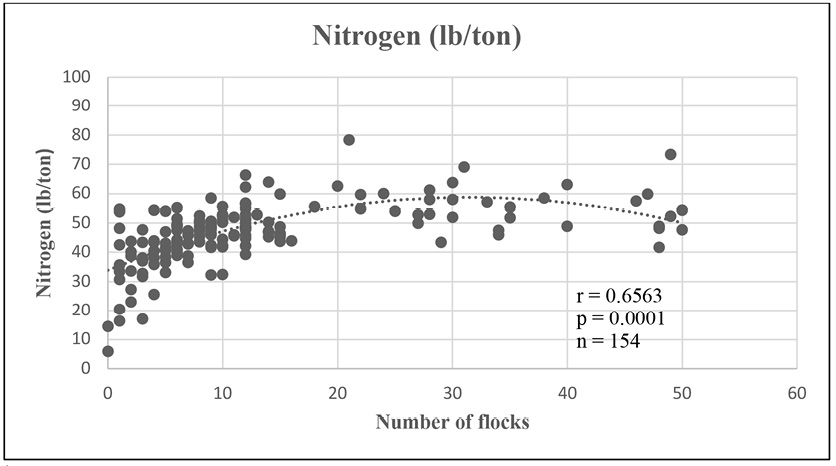

Espinoza et al. (2005) reported broiler litter samples analyzed by the University of Arkansas Agricultural Diagnostic Laboratory between 1993 and 2001 had an average N, P2O5, and K2O content of 60, 57, and 52 pounds per ton, respectively (Table 4). Tabler et al. (2015) reported that Mississippi broiler litter contained 47.44, 69.39, 61.37, and 9.22 pounds per ton of N, P2O5, K2O, and WEP, respectively (Table 5). Based on the number of flocks grown on the same litter, Tabler et al. (2015) indicated that nutrient concentrations of N, P2O5, K2O, and WEP in broiler litter tended to increase until approximately 15 flocks had been grown and then tended to stabilize, regardless of how many additional flocks were grown. Figure 1 illustrates the effect of number of flocks on pounds of N per ton of litter. Similar results were seen for P2O5, K2O, and WEP.

Patterson et al. (1999) reported as-is litter production to be 0.558 and 0.488 pound per pound (lb/lb) of live weight for litter that was used for two to three flocks and one to two flocks, respectively. For litter used for six (1993), five (1994), seven (1995), and nine (1996) flocks, Tabler et al. (1997) reported as-is litter production to be 0.369, 0.466, 0.407, and 0.416 lb/lb of live weight, respectively (Table 2). Coufal et al. (2006) observed litter production to be 0.606 and 0.550 lb/lb of live weight for two flocks, respectively. Starting litter depth and density, litter moisture content, and broiler harvest weight could account for some of these differences.

Summary

Nutrient content characteristics of broiler litter can be extremely variable. This underscores the importance of correctly sampling and analyzing litter before it is spread because, otherwise, there is no way to know its fertilizer value. Broiler growers and integrators can use the information presented here to estimate the amount of litter material generated over a wide range of flocks grown on the same litter. Nutrient analysis of this litter material, when coupled with the estimated amounts, will allow broiler growers to estimate the total nutrient content available from their litter materials. This information will prove increasingly valuable as land application of litter is being closely scrutinized regarding short- and long-term environmental impacts, especially as it relates to phosphorus runoff and its potential role in accelerating eutrophication.

| Date | Flock length (days) | Flocks on same litter | pH | Moisture (%) | Ash (%) | lb/ton on as-is basis | |||

|---|---|---|---|---|---|---|---|---|---|

| N | P2O5 | K2O | Ca | ||||||

| Jun-95 | 41 | 1 | 7.4 | 33.1 | 19.6 | 33.8 | 42.5 | 36.6 | 36.2 |

| Aug-95 | 41 | 2 | 7.6 | 31.5 | 22.5 | 43.6 | 47.9 | 44.1 | 43.0 |

| Oct-95 | 41 | 3 | 7.6 | 28.7 | 26.2 | 51.8 | 57.7 | 45.6 | 46.1 |

| Dec-95 | 40 | 4 | 7.2 | 33.8 | 24.6 | 51.0 | 51.0 | 44.2 | 42.6 |

| Feb-96 | 45 | 5 | 6.9 | 36.0 | 24.4 | 55.3 | 52.9 | 48.4 | 43.2 |

| Mar-96 | 41 | 6 | 7.5 | 34.7 | 24.9 | 53.0 | 52.8 | 45.6 | 41.2 |

| May-96 | 42 | 7 | 7.8 | 27.3 | 24.0 | 62.9 | 58.2 | 52.9 | 47.4 |

| Jun-96 | 42 | 8 | 7.3 | 28.7 | 26.0 | 49.5 | 59.3 | 54.2 | 47.3 |

| Aug-96 | 43 | 9 | 7.8 | 22.3 | 22.6 | 60.3 | 69.3 | 58.3 | 53.5 |

1Adapted from Tabler and Berry (2003).

2Initial bedding material was 50:50 mix of rice hulls and pine shavings/sawdust.

3Figures are averages of four 40-by-400-foot houses on the farm.

| Date | Flock age (weeks) | # of flocks | pH | Moist (%) | Ash (%) | lb/ton on as-is basis | Depth (in) | Density (lb/ft3) | lb litter2/ lb chicken | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N | P2O5 | K2O | Ca | |||||||||

| Apr-93 | 8 | 6 | 7.25 | 23.78 | 57.7 | 57.0 | 64.1 | 41.7 | 6.44 | 30.50 | 0.369 | |

| Apr-94 | 8 | 5 | 6.87 | 28.13 | 27.20 | 58.1 | 68.0 | 49.1 | 51.0 | 5.13 | 37.09 | 0.466 |

| Apr-95 | 6 | 7 | 7.61 | 25.04 | 26.61 | 55.9 | 66.1 | 52.5 | 53.2 | 3.96 | 35.14 | 0.407 |

| Aug-96 | 6 | 9 | 7.80 | 23.09 | 23.87 | 57.5 | 68.4 | 58.0 | 54.2 | 4.64 | 41.58 | 0.416 |

| Average | 7.38 | 25.01 | 25.89 | 57.3 | 64.9 | 55.9 | 50.0 | 5.04 | 36.08 | 0.415 | ||

1Adapted from Berry (1997).

2Weight is on as-is basis.

| Factor | Sample size | Minimum | Maximum | Average |

|---|---|---|---|---|

| Moisture, % | 297 | 13 | 67.2 | 30.8 |

| pH | 297 | 5.6 | 9.4 | 8.4 |

| N, lb/ton | 297 | 20 | 88 | 62 |

| P2O5, lb/ton | 297 | 27.5 | 119.1 | 68.7 |

| K2O, lb/ton | 297 | 2.6 | 81.6 | 62.4 |

| WEP2, lb/ton | 297 | 0.5 | 9.9 | 1.9 |

1Adapted from Sharpley et al. (2009).

2Water-extractable phosphorus.

| Factor | Minimum | Maximum | Average |

|---|---|---|---|

| Moisture, % | 2 | 47 | 23 |

| N, lb/ton | 22 | 98 | 60 |

| P2O5, lb/ton | 18 | 96 | 57 |

| K2O, lb/ton | 23 | 80 | 52 |

1Adapted from Espinoza et al. (2005).

| Division | # of farms | # of flocks | pH | Moisture % | lb/ton | |||

|---|---|---|---|---|---|---|---|---|

| N | P2O5 | K2O | WEP | |||||

| 1 | 18 | 7.28c | 7.48ab | 24.46efg | 44.08bc | 43.13c | 61.84ab | 9.58bcd |

| 2 | 20 | 7.95c | 6.67f | 25.35defg | 44.42bc | 50.78c | 61.94ab | 6.59ef |

| 3 | 18 | 5.94c | 7.61a | 23.85gf | 38.76c | 52.53c | 59.94ab | 4.95f |

| 4 | 20 | 8.05c | 7.19cd | 27.23bcd | 46.68b | 55.23c | 60.23ab | 13.38a |

| 5 | 4 | 11.25c | 7.27bc | 27.11def | 47.42b | 73.49b | 60.16ab | 9.40cd |

| 6 | 10 | 22.40b | 7.12cd | 26.39cde | 47.08b | 77.24ab | 57.37b | 8.00de |

| 7 | 10 | 10.50c | 6.84ef | 28.95ab | 49.46b | 74.78b | 59.19ab | 9.52bcd |

| 8 | 16 | 12.87c | 7.14cd | 25.73def | 45.52b | 75.82b | 66.86a | 10.83bc |

| 9 | 7 | 34.43a | 6.81ef | 26.71cd | 46.61b | 78.65ab | 57.02b | 10.45bc |

| 10 | 12 | 12.58c | 6.71f | 27.92ab | 49.84b | 85.99ab | 59.67ab | 10.47bc |

| 11 | 18 | 25.22b | 6.99de | 28.37g | 60.85a | 89.30a | 64.73ab | 11.29b |

| 12 | 5 | 6.20c | 7.10cd | 30.26a | 48.56b | 75.78b | 67.44a | 6.16f |

| Average | 13.72 | 13.72 | 7.08 | 26.86 | 47.44 | 69.39 | 61.37 | 9.22 |

1Adapted from Tabler et al. (2015).

abcdefgMeans within a column not sharing a common subscript differ significantly (P < 0.05).

References

Berry, I. L. (1997). Litter production at the Broiler Energy Project. In: Progress report: Broiler Energy project 1995–97 (pp. 9–10). Center of Excellence for Poultry Science, Cooperative Extension Service, Agricultural Experiment Station, University of Arkansas, Fayetteville.

Chamblee, T. N., & Todd, R. L. (2002). Mississippi broiler litter: Fertilizer value and quantity produced. Mississippi Agriculture and Forestry Experiment Station (MAFES) Research Report. Vol. 23(5).

Coufal, C. D., Chavez, C., Niemeyer, P. R., & Carey, J. B. (2006). Measurement of broiler litter production rates and nutrient content using recycled litter. Poultry Science, 85, 398–403.

Espinoza, L., Slaton, N., Mozaffari, M., & Daniels, M. (2005). The use of poultry litter in row crops. University of Arkansas Cooperative Extension Service Fact Sheet. FSA2147.

Malone, G. W. (1992). Nutrient enrichment in integrated broiler production systems. Poultry Science, 71, 1117–1122.

Malone, G. W., Sims, T., & Gedamu, N. (1992). Quantity and quality of poultry manure produced under current management programs. Final report to Delaware Department of Natural Resources and Environmental Control and Delmarva Poultry Industry Inc., University of Delaware, Research and Education Center, Georgetown, Delaware.

Natural Resource, Agriculture, and Engineering Service (NRAES). (1999). Poultry waste management handbook. Cooperative Extension, Ithaca, NY.

Patterson, P. H., Lorenz, E. S., Weaver Jr., W. D., & Schwartz, J. H. (1998). Litter production and nutrients from commercial broiler chickens. Journal of Applied Poultry Research, 7, 247–252.

Sharpley, A., Slaton, N., Tabler, T., VanDevender, K., Daniels, M., Jones, F., & Daniel, T. (2009). Nutrient analysis of poultry litter. University of Arkansas Cooperative Extension Service Fact Sheet. FSA9529.

Tabler, T. (1999). Unpublished data.

Tabler, T. (2000). How much litter do broilers produce? Avian Advice, 2(1), 6–8.

Tabler, G. T., & Berry, I. L. (2003). Nutrient analysis of poultry litter and possible disposal alternatives. Avian Advice, 5(3), 1–3.

Tabler, T., Brown, A., Hagood, G., Farnell, M., McDaniel, C., & Kilgore, J. (2015). Nutrient content of Mississippi broiler litter. Mississippi State University Extension Service, Publ. No. 2878.

VanDevender, K., Langston, J., & Daniels, M. (2000). Utilizing dry poultry litter: An overview. Arkansas Cooperative Extension Service, FSA8000. University of Arkansas, Little Rock, Arkansas.

Publication 3601 (POD-04-21)

By Tom Tabler, PhD, Extension Professor, MSU Poultry Science; Yi Liang, PhD, Associate Professor, Biological and Agricultural Engineering Department, University of Arkansas; Jessica Wells, PhD, Assistant Clinical/Extension Professor, MSU Poultry Science; and Jonathan Moon, Poultry Operation Coordinator, MSU Poultry Science.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.