Water is the most important nutrient for the overall health and performance of commercial broilers. It plays an essential role in every aspect of metabolism and is critical to the regulation of the bird’s body temperature, food digestion, and waste elimination. By weight, broilers consume almost twice as much water as feed. During its lifetime, a 5-pound broiler will consume about 18 pounds of water, compared to approximately 10 pounds of feed (Lacy, 2002).

An adequate water supply is important to ensure that enough water is actually available to your birds. Today, almost every broiler grower has houses with some form of nipple water system that should provide one nipple per 10 to 12 birds (Tabler, 2003). An adequate number of nipples is critical, but perhaps even more important is an adequate flow rate from those nipples.

Low water flow rates can decrease flock performance (Lott et al., 2003). Research shows that adequate flow rates (ml/minute) could be estimated by multiplying 7 ml by bird age in weeks and adding 20. Therefore, adequate nipple flow rates for 8-week-old broilers would be 7 × 8 = 56 + 20 = 76 ml/min. A system that delivers more than this is not a problem when managed properly, but one that delivers less can restrict flow and reduce performance.

Broiler water intake is directly related to a variety of factors, including water quality (Barton, 1996) and diet composition (Belay and Teeter, 1993). However, perhaps the most important factor affecting broiler water intake patterns is environmental temperature. Water evaporation through the respiratory system (panting) is one of the main ways birds regulate body temperature during heat stress conditions. Broilers increase water consumption approximately 7 percent for each degree increase in temperature (Fairchild and Ritz, 2012).

Taste can have a big impact on water consumption in broilers. Chickens have a keen sense of taste and prefer water that is slightly acidic (Kare, 1970). This may explain why broiler growers who have run vinegar in the past may have noticed a slight increase in water consumption while doing so. However, unlike most animal species, a chicken’s taste buds, for the most part, are not on the tongue. Taste buds in the chicken are distributed primarily on the back part of the roof of the mouth, with only 2 to 4 percent located on the tongue (Ganchrow and Ganchrow, 1985).

In addition to taste, water temperature plays a major role on water intake in birds. Birds will drink cold water that is near freezing in temperature. However, they will suffer from extreme thirst rather than drink water that is a degree or two above their body temperature (Jones and Watkins, 2009). As long as water temperature is below body temperature, the bird receives some benefit from drinking because it helps with heat dissipation and body temperature regulation.

Lighting, either natural or artificial, affects water intake. With increased use of solid sidewall and dark-out housing, artificial lighting is replacing natural light. With natural lighting, two peaks in water consumption usually occur. The first is at dawn, as the sun comes up and the birds become active. The second is at dusk, as light levels begin to fade and the birds increase intake just before “bedding down for the night.”

With artificial lighting, we see much the same pattern. Water intake increases when the lights first come on and increases again just before the lights go off. The birds “learn” what time the lights go off, and increase consumption just before this “bedding down” time. Therefore, whenever you make a change to your lighting schedule, always change the “on” time, and not the “off” time, so as not to disrupt the intake pattern the birds have established at “bedtime.”

Feed availability will have a major influence on water intake. Feed and water consumption are very closely correlated. The birds will drink little water, even if it is available, if they do not have access to feed. And they will eat little or no feed if they do not have access to water.

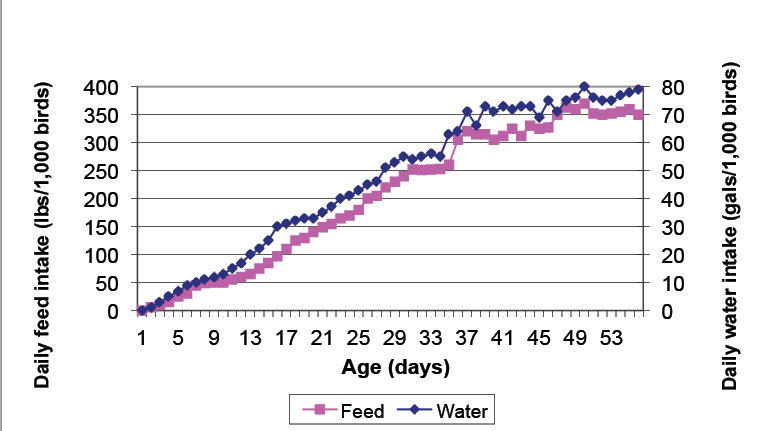

Figure 1 shows daily feed and water consumption patterns for a flock of 56-day male broilers. Notice that, on most days, when water intake goes up, feed intake also goes up. The same is true if intake goes down. If you read your water meters daily, this can give you a fair assessment of flock performance. Even though you aren’t weighing the feed, you know that if water intake is up today from yesterday, then most likely the birds ate more feed today than yesterday.

Modern controllers can usually be programmed to read the water meters for you, so if you look back in the controller’s history, you’ll have an idea of the water intake pattern for the flock. If you record the daily water intake history before the controller’s history is cleared out for a new flock, you can gradually build a database of water intake on your farm. You might then use this to recognize problems or unusual consumption patterns later on. You can also compare the current flock’s intake pattern with that of previous flocks to estimate performance at any time throughout the flock.

Knowing the peak demand for water will help you ensure an adequate water supply. This information is critical when sizing well pumps and supply lines from the water source to the chicken houses. Installing a pump that is too small and/or pipe that is too small in diameter will mean the system cannot maintain an adequate supply of water for drinking and cooling needs, especially in hot weather during times of peak demand.

A typical 500-foot broiler house requires about 2 gallons per minute to meet the drinker demand, so an eight-house complex would need a 16 gpm water supply, just to meet basic drinking water needs. However, evaporative cooling systems usually require an additional 8 gpm per house, bringing the total water requirement per house up to 10 gpm.

This means that an eight-house farm would need a flow rate of 80 gpm (10 gpm/house × 8 houses = 80 gpm) and require a 3-inch PVC main supply line from the well. You will not need this much capacity for the entire year. In fact, you may only need it for a few weeks during the summer when the birds are big. However, you must size the system to meet the peak demand when you have big chickens and hot weather.

If long runs or large differences in elevation exist from the well to the chicken houses, larger pipes may be needed. Pump size is also a factor. Use a pump capable of delivering more than peak demand as a safety precaution. Proper pump sizing depends on several factors, including depth of the well, length of the run and the associated pressure loss in piping between the well and chicken houses, and change in elevation between the well and the houses. Pressure loss in the piping system should be such that you still have at least 40 to 50 pounds per square inch at the chicken house; this typically means pressure at the wellhead is around 50 to 60 pounds per square inch.

Many growers have less than high-quality water supplies. Therefore, water filters are a common item on broiler farms. Unfortunately, filters can become clogged rapidly (especially during hot weather) and restrict water flow to drinking and cooling systems. So monitor filters closely and change them regularly, because an adequate supply and plenty of pressure will be of little value if water can’t get through the filter. Many water filters today have smaller micron sizes than filters from a few years ago, so they will clog more quickly and need changing more often. Therefore, keep plenty of spares for both the drinking and cooling systems.

Summary

Numerous factors, including water temperature and taste, feed availability, drinker flow rate, and lighting programs, will affect water intake. The correct pump and pipe size are important to prevent water restriction problems. An adequate supply of good-quality water is critical for optimum broiler performance. If you have questions, consult a design engineer for assistance determining proper piping and pump size, or contact your local MSU Extension office with any water-related issues.

References

1992 Annual Report. Broiler Research Verification for Energy Efficiency and Optimum Production. Coop. Ext. Serv. and Agri. Exp. Sta., University of Arkansas, Fayetteville.

Barton, T. L. 1996. Relevance of water quality to broiler and turkey performance. Poultry Science, 75: 854–856.

Belay, T. & R. G. Teeter. 1993. Broiler water balance and thermobalance during thermoneutral and high ambient temperature exposure. Poultry Science, 72: 106–115.

Fairchild, B. D. & C. W. Ritz. 2012. Poultry drinking water primer. Bull. 1301. Cooperative Extension, University of Georgia, Athens.

Ganchrow, D. & J. R. Ganchrow. 1985. Number and distribution of taste buds in the oral cavity of hatchling chicks. Physiological Behavior, 34(6): 889–894.

Jones, F. T. & S. E. Watkins. 2009. How does taste influence water consumption in broilers? Avian Advice, 11(1): 8–11.

Kare, M. R. 1970. The chemical senses of birds. Bird Control Seminars Proceedings. Available online at http://digitalcommons.unl.edu/cgi/viewcontent.cgi?article=1183&context=icwdmbirdcontrol.

Lacy, M. 2002. Broiler management. In D. B. Bell and W. D. Weaver (eds), Commercial Chicken Meat and Egg Production (pp. 829–868). Norwell, MA: Kluwer Academic Pub.

Lott, B. D., W. A. Dozier, J. D. Simmons & W. B. Rouch. 2003. Water flow rates in commercial broiler houses. Poultry Science, 82(Suppl. 1): 102(S56).

Tabler, G. T. 2003. Water intake: A good measure of broiler performance. Avian Advice, 5(3): 7–9.

The information given here is for educational purposes only. References to commercial products, trade names, or suppliers are made with the understanding that no endorsement is implied and that no discrimination against other products or suppliers is intended.

Publication 2742 (POD-10-21)

By Tom Tabler, PhD, former Extension Professor, Poultry Science; Jessica Wells, Assistant Clinical/Extension Instructor, Poultry Science; and Wei Zhai, PhD, former Assistant Professor, Poultry Science.