There are many factors that contribute to successful and proper insemination but one of the most prominent and obvious factors is the process of the insemination itself. It’s important to understand all aspects of this process. Hybrid Turkeys has recommendations that can help guide you towards the best prosperity for your flock.

Pre-milking before first insemination

Healthy toms produce good quality, and more consistent semen. One week before semen is to be used for insemination, all toms should be pre-milked 2 times. If you identify toms that do not produce, or poorly produce semen do not use them for the insemination process. They should be marked and rechecked weekly to see if they improve.

It’s important to allow enough rest time for toms in between milking. We recommend not using more than 2 times per week with 2 days rest between milking and ensuring toms do not go more than a week without being milked.

Lighting is a huge factor and using the correct lighting program, will make a difference in the tom’s semen production. It is very critical to not have any light leaks on the toms and that light intensity stimulation should increase around 8 weeks before the insemination starts.

High quality collection

Semen quality heavily influences the outcome of the insemination. Make sure what you are collecting from your toms is high quality for the best chance of success. Visually, only thick, white semen is acceptable. Off colored, thin, urates, feces, or blood in the semen will cause lower fertility.

Check all extender bottles before using, and never add extender when it’s cold or room temp. In a lab it’s recommended to use a shaker or agitator, with an ice slush. It’s also necessary to have one in the semen car, and barn. If you are not using a lab, ensure you are using a filter. Change barn semen filters every 3 to 5 toms to reduce any fecal material on the filters, which could result in damaged quality semen.

Use semen in order of when it was produced. The best practice is to mark all bottles with the number and then the time milked. For example, 1-615, 2-635, 3-650. Most importantly, these collections must be used as soon as possible. If studs are not on the farm with the hens, this is where the shaker/agitator, along with using the bottles in order becomes very important. We recommend not using semen that was collected longer than 6 hours previously.

Methods

Using a pit to conduct the inseminations or through using an artificial insemination chair are the two main methods commonly used for artificial turkey insemination. Regardless of which method you are using it’s important that every hen who is ready, is inseminated. If you observe semen on the outside of the oviduct after injection, you are not injecting deep enough. Keep in mind that insemination requires the right amount of labor to be completed successfully. Ensure you have enough staff on hand to make the process as seamless as possible and remember not to overcrowd the pens in the process.

What do fertile and infertile eggs look like?

Fertile

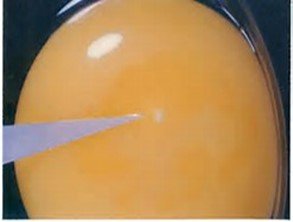

- The germinal disc is faint: Not a solid white spot.

- The germinal disc consists of a faint white ring which may have a solid white spot in the center of the ring.

Infertile

- The germinal disc is a solid white spot on the yolk.

- The germinal disc is not uniform. It is somewhat circular but has “jagged” or “ruffled” edges.

- It can take about 48 hours of incubation in order for a non-trained eye to see if an egg is fertile vs infertile.

Proper lighting

Lighting is another factor that can affect the egg production of a breeder hen. The flocks lighting program can positively or negatively affect peaks, along with the life of the flock performance. What works in one barn, may not work in another barn because all barns are not the same. With different square footage, number of lights and type of bulbs used, and if your barn has solid walls or is curtain sided will all influence what is required for the proper lighting program.

It’s best practice to inspect your barns regularly for light leaks and check the light time clock or control panel daily to ensure they are getting the correct light intensity. Never decrease morning light stimulation or day-length stimulation for a flock in production. Adding additional light in the morning or beginning of the day will help train your hens to lay in the morning and not in the late afternoon when workers are ready to go home. It also helps reduce the number of ground eggs.

For proper insemination, nothing replaces good management practices. With many factors contributing to successful and proper insemination, it’s critical that you know your birds, your farm and keep up with production daily. For more information or customized recommendations on breeder management please reach out to a member of our Hybrid Turkeys Technical Service Team.