General Production Information

- Poultry is the top agricultural industry in North Carolina, with an economic impact of $36.6 billion in 2016 (North Carolina Poultry Federation 2018).

- In 2017, North Carolina ranked second in turkey production by number of head (32.5 million) but first in pounds (1.14 billion) and farm gate value ($739.02 million) (National Agricultural Statistics Service, USDA 2018).

- In 2017, North Carolina was fourth in broiler production (830.8 million), representing 9.3 percent of U.S. production, and was third in pounds produced (6.56 billion) (National Agricultural Statistics Service, USDA 2018).

- In 2012, North Carolina ranked first nationally in cash receipts from poultry and egg products ($4.8 billion), representing 9.5 percent of the U.S. production (National Agricultural Statistics Service, USDA 2017).

- In 2012, North Carolina ranked eighth nationally in the number of layer chickens (13 million head) (National Agricultural Statistics Service, USDA 2017).

Production Regions

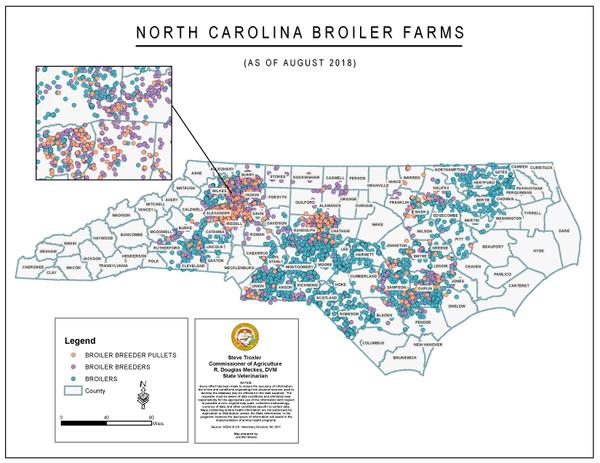

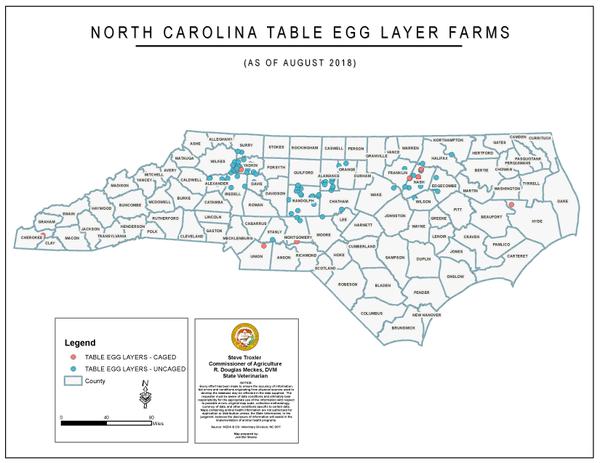

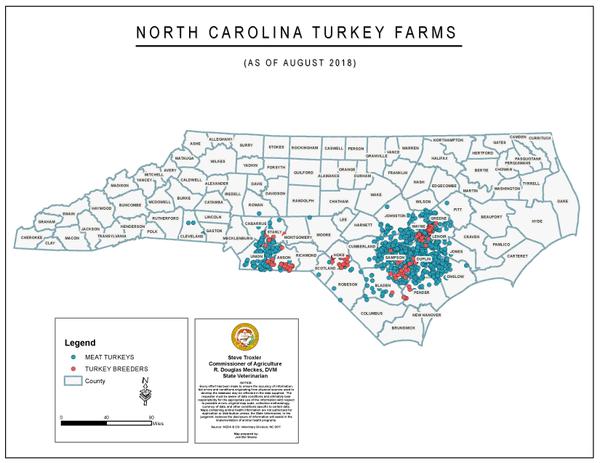

Chicken production (layers, broiler breeders, and broilers) essentially extends from Gates, Pitt, Craven, and Pender counties in the east to Cleveland, Burke, Caldwell, and Ashe counties in the west. North Carolina’s turkey production region follows a similar east to west distribution but extends no farther north than Pitt, Chatham, and Iredell counties. There are two distinct areas of concentrated turkey production within this region: an eastern area centered around Sampson, Duplin, and Wayne counties and a western area centered around Union, Anson, and Stanly counties. Figure 1, Figure 2, and Figure 3 illustrate the highest-ranked counties for broiler, chicken (except commercial broilers), and turkey-producing, respectively, in North Carolina.

Cultural Practices

Commercial poultry production is predominantly a vertically integrated system in North Carolina. Production companies (integrators) contract with growers to produce birds or eggs. The integrator supplies birds and feed, as well as supplemental materials such as medications and pesticides, to the grower. The integrator is also responsible for hatchery management, transport, slaughter, and marketing. The grower builds and maintains the houses, installs and maintains equipment, handles daily flock management, and disposes of dead birds and waste.

Birds are housed in large structures with floor areas ranging from 12,000 square feet to more than 36,000 square feet. Buildings are equipped with automated feeders and either bell-type, nipple, or cup watering systems. Broilers and turkeys are raised on deep litter (wood shavings) in open-floor environments where birds can move freely throughout the house. A production cycle for broilers generally lasts six weeks; birds are then removed to market. A new flock of day-old broilers is placed in the broiler house within two to four weeks, allowing time for the grower to clean and disinfect the building. Waste removal in broiler houses has shifted from annual cleanouts to once every two or more years.

Turkey production schedules and methods are slightly different. Young turkeys are most often placed in brooder houses for the first six weeks of life, then moved to grow-out houses until they are sold to market after another 12 to 18 weeks of growth. A two- to four-week period is allowed before a new flock is placed in either turkey brooder or grow-out houses to allow for cleaning and disinfection. Litter waste (manure mixed with litter) is generally removed from turkey grow-out houses once a year. Old litter is typically replaced after each flock is removed from turkey brooder houses.

Broiler-breeder hens are first housed in open-floor environments or pens where they are reared to 20 to 22 weeks of age. The arrangement and management of these houses are similar to those described for broilers. Roosters are similarly housed until breeding age. The breeding flock (hens and roosters) is then transferred to production houses where hens begin to lay fertile eggs at about 24 weeks of age. The birds are held in production for an additional 36 to 44 weeks, when they are sold to the market.

Production broiler-breeder flocks are confined in modified open-floor housing, where two thirds of the space (along walls) consists of a raised, slatted floor. Most of the manure collects beneath these slats. The remaining central portion of the floor (scratch area) consists of deep litter. Water and feed lines are located over the slatted area of the house. Automated nest boxes are positioned down the length of the house along the raised slats on both sides of the scratch area. Once the broiler-breeder flock is removed, nest boxes and slats are taken from the building to allow a thorough cleanout. Manure and litter are removed, the building and equipment are washed and disinfected, and the system of slats and nest boxes is reinstalled for a new flock of birds. Several months often elapse between flocks.

Layer pullets are first placed in cages or open-floor environments for six to eight weeks. Floor-reared birds are transferred to rearing cages until ready for production. All layer pullets are then reared in cages until they are 18 to 20 weeks of age, when they are transferred to production housing. Laying flocks are held in production until about 75 weeks of age.

Commercial layers are confined to cages (three to four birds per cage) within buildings. Rows of cages are most often tiered three to four cages high, each tier slightly offset from the one below to prevent droppings from contaminating the birds in lower cages. Four to eight rows of tiered cages extend the length of the house. Rows are arranged back to back so that three to five walkways can be used for inspection and maintenance. Automated feeders and cup or nipple drinkers provide food and water to each cage. An automated egg-handling system collects eggs as they are laid. Manure may be allowed to collect in a deep pit beneath cages, or it may be flushed into a lagoon. Manure collected in deep-pit designs (high-rise housing) accumulates until the layer flock is removed; liquid waste-handling systems are flushed daily. The cleanout interval between flocks is similar to that for broiler breeders, although the cages and equipment are generally left in place while the building is cleaned and disinfected.

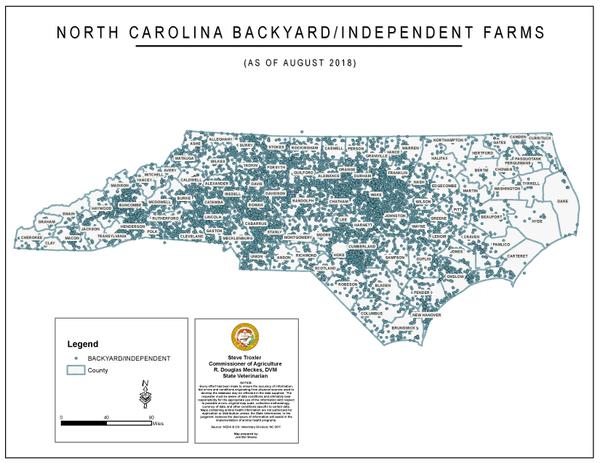

The number of backyard poultry flocks has increased throughout North Carolina (Figure 4). Backyard flocks tend to be highly variable in the number of birds, breeding (mixed strain), bird age, housing, and biosecurity practices. Free range birds have greater access to the outdoors and often carry more ectoparasites than more managed birds (Murillo and Mullens 2016). Owners of backyard flocks may be challenged by pest management issues.

Worker Activities

Risks associated with pesticide application in poultry production are greatest during the handling and mixing of concentrates prior to application. The most likely exposure events are spills and splashing during mixing, as well as airborne particulates being released while loading applicators. Dermal, oral, and inhalation exposure during premise treatment are also possible. Exposures due to splash and aerosol drift are highest during the application of high-pressure sprays (75 to 100 psi) used to suppress difficult to control pests, as well as with dust treatments using high-volume, power applicators. Exposure risks during premise treatment are reduced where low-pressure application (less than 50 psi) is prescribed, and where dust application is limited to litter surfaces using gravity-fed equipment.

Control of ectoparasites on poultry creates additional exposure risks. High-pressure sprays or dipping may be used in large commercial operations to treat birds for obligate ectoparasites such as the northern fowl mite. In both situations, the applicator risks breathing aerosol particulates or being splashed by chemicals.

Routes of entry may be oral, dermal, or inhalation. Dipping represents the most significant risk to personnel since each bird must be handled to effectively treat for parasites. A significant amount of splash occurs as birds are immersed and withdrawn from the dipping solution. Commercial flocks are seldom treated with dusts to control ectoparasites. Pesticide-impregnated plastic strips are sometimes used as an alternative for spray or dip treatments. These devices are hung in cages or nest boxes, allowing the birds to self-apply the active ingredient as they brush against the strip. Dermal and oral exposure risks are of possible concern for individuals hanging these devices, primarily because workers handle a large number of strips during installation.

Pesticide exposure to residues on surfaces, eggs, and birds is minimal, representing little risk to workers. Once treated, birds are seldom handled by workers until they are removed from the houses at the end of a production cycle. Frequency of application also plays a role in reducing secondary exposure following premise treatments. Poultry houses are often treated just prior to the introduction of a new flock. In the case of broilers and young turkeys, premise treatments will occur at least every seven to eight weeks.

Treatment intervals in turkey grow-out houses are approximately twice those of broilers, and intervals for breeder and layer operations can extend from 40 weeks to more than one year. Where exposure to large areas of treated surface occurs, as in open floor production systems for broilers and turkeys, the primary contact point is the litter. The highly reactive chemical and biological environment of poultry litter and manure degrades many of the labeled pesticides within one to two weeks. Manure that accumulates beneath slats in broiler breeder houses or in the pit area of high-rise layer houses is sometimes treated with larvicides (pesticides or insect growth regulators targeting the immature lifestages). Because workers and birds are not in direct contact with the wastes, there is little risk of secondary exposure. Exposure risks are also minimal when the manure is removed from these houses since decomposition processes will have eliminated much of the applied pesticide. However, some insect growth regulators (IGRs) may persist in the manure through the cleanout phase.

All of the worker exposure risks discussed here are significantly reduced by using recommended protective equipment and by safely mixing, loading, and applying the chemicals.

Insect Pests

Two broad categories of pests affect poultry: ectoparasites—mites and insects living and/or feeding on poultry (mites, lice, bed bugs) and structural or environmental pests—flies, mosquitoes, litter beetles, dermestid beetles, cockroaches, spiders, and red imported fire ants. This latter category of pests, associated with the environment of modern confinement poultry production, directly damages poultry structures, is a potential or documented vector of disease and avian parasites, or is a source of nuisance.

Ectoparasites

Ectoparasite infestations are infrequent and typically limited to breeding flocks, layers, and backyard flocks. Broilers and market turkeys are seldom if ever affected. Management of ectoparasites largely consists of whole flock treatments whenever infestations are detected by scouting birds and/or inspecting the structure and equipment (nest boxes, curtains, slats, cages). No other effective management techniques are available. It is estimated that slightly more than 4 percent of breeder birds and layers are treated for ectoparasites each year. Pesticides are applied directly to the birds for control of northern fowl mites and poultry lice.

The average number of treatments applied directly to birds ranges from 1.2 to 5.5. Premise treatments are most often applied to control red chicken mites, bed bugs, and poultry lice. Permethrin, pyrethrins, tetrachlorvinphos, and RaVap (dichlorvos + tetrachlorvinphos) are applied to the birds as well as the premises. Dichlorvos is occasionally used as a flushing agent/toxicant space spray for bed bugs.

Cyfluthrin may also be used as a premise treatment to control bed bugs as long as birds are not present.

Varying levels of pyrethroid resistance in fowl mites are prevalent in the United States. Resistance in poultry lice and bed bugs appears to be minimal; however, human-associated bed bug resistance is a serious concern. The availability of tetrachlorvinphos and dichlorvos as alternative treatments is therefore essential to manage resistance unless new classes of compounds become available.

Structural and Environmental Pests

This category of pests is widespread and affects every stage of poultry production to a greater or lesser extent. The house fly (Musca domestica) and other fly species with similar biology and habits can generally be managed with minimal use of pesticides where appropriate cultural and biological control practices are most effective (broiler breeders and layers). Manure management to decrease moisture reduces fly-breeding potential and enhances the effectiveness of naturally occurring fly parasites and predators. Releases of beneficial insects (primarily parasitic wasps) can also be effective in the control of flies in broiler-breeder and layer operations. Trapping is useful where fly populations are relatively low. However, manure moisture and biological control are difficult to manage throughout an entire flock cycle. Traps are difficult to maintain and are quickly overwhelmed when other elements of the management system fail. Failures occur frequently and require the use of insecticides to reduce fly populations. More than half (54 percent) of producers are estimated to use insecticides to control a variety of fly pests.

Other pests such as the lesser mealworm (also known as darkling beetle or litter beetle) (Alphitobius diaperinus) and the dermestid beetle (Dermestes maculatus) are also prevalent in poultry houses. Lesser mealworms are by far the most serious problem, prompting approximately 81 percent of producers to apply pesticides for beetle control. Red imported fire ants, spiders, mosquitoes, and cockroaches may also infest poultry houses and account for a little more than 10 percent of the pesticides applied. Cultural and biological control practices are largely ineffective for these pests, requiring between-flock applications of insecticides to control their populations.

Insecticides used to control some or all of these structural/environmental pests include those already mentioned (tetrachlorvinphos, dichlorvos, permethrin, pyrethrin, and cyfluthrin), as well as lambda-cyhalothrin, esfenvalerate, orthoboric acid, methomyl, cyromazine, imidacloprid, and nithiazine. Carbaryl has lost its registration for use inside poultry houses, and so is of little practical value to the industry.

Pyrethroid insecticide resistance among house fly populations is well documented in the United States. In North Carolina, house fly populations displayed variable resistance from site to site, with some populations exhibiting 60 to 80 percent survival to methomyl, cyfluthrin, and pyrethrins + PBO. Survival was nearly 100 percent following exposure to permethrin. Pyrethroid resistance among other structural/environmental pests is not believed to be substantial at present, with the exception of the lesser mealworm, which is showing significant levels of resistance to cyfluthrin and tetrachlorvinphos. Because these compounds serve as the mainstay of lesser mealworm control in North Carolina, it is likely that a similar resistance profile exists here. Restrictive labeling for carbaryl has effectively removed its value for poultry growers as a premise treatment. The availability of tetrachlorvinphos and dichlorvos is believed to be more essential than ever to control key premise pests. The limited catalog of effective pesticides that presently exists is a primary concern for the North Carolina poultry industry. The introduction of new classes of compounds for use in poultry production is minimal, and the outlook for new and economical options for managing resistance is not promising for pests with no effective management alternatives other than pesticides.

Chemical Controls

Dichlorvos (Vapona)

This material is available as an emulsifiable concentrate. Treatments are most often used for fly control. It is applied as either a space spray (0.001 pound of active ingredient per 1,000 cubic feet) or as a premise spray (0.01 pound of active ingredient per 1,000 square feet of surface area). Dichlorvos is occasionally used as a spot larvicide treatment for fly control at a rate of 0.002 to 0.02 pound active ingredient per 100 square feet of manure beneath slats, cages, and drinkers. An estimated 802,000 square feet (0.4 percent) of premise area are treated with dichlorvos.

Dimethoate (Dimate 4E)

This product is applied for house fly and maggot control in poultry manure.

Tetrachlorvinphos (Rabon)

Available as a dust and wettable powder, tetrachlorvinphos is applied to about 18 percent of the birds treated for ectoparasites and 10 percent of premise area (20 million square feet) to control various pests. Treatments are generally applied as high-pressure sprays at a rate of 1 gallon of spray (0.04 pound of active ingredient) per 100 birds. Premise applications for a variety of pests are made at a rate of 0.05 to 0.8 pound of active ingredient per 1,000 square feet of surface area. Dust formulations are applied to birds (dust boxes) at a rate of 0.01 to 0.2 pound of active ingredient per 100 birds, and to premises for ectoparasites and beetles at a rate of 0.05 to 0.2 pound active ingredient per 1,000 square feet of surface area. Rabon is occasionally used as a spot larvicide treatment for fly control at a rate of 0.08 pound of active ingredient per 100 square feet of manure beneath slats, cages, and drinkers.

Tetrachlorvinphos + dichlorvos (RaVap)

Available as an emulsifiable concentrate, RaVap is applied to approximately 10 percent of the birds treated for ectoparasites and 7 percent of premise area (14 million square feet) for a variety of pests. Treatments are applied as high-pressure sprays at a rate of 0.04 pound tetrachlorvinphos + 0.01 pound dichlorvos per 100 birds. Premise applications are made at a rate of 0.04 + 0.01 pound to 0.08 + 0.02 pound of active ingredient per 1,000 square feet of surface area for a variety of pests in poultry houses. RaVap is occasionally used as a spot larvicide treatment for fly control at a rate of 0.08 + 0.02 pound active ingredient per 100 square feet of manure beneath slats, cages, and drinkers.

Methomyl (Apache, Golden Malrin)

Available for fly control, methomyl is used as a scatter bait or in fly traps at a rate of 0.005 pound active ingredient per 1,000 square feet. Estimated usage has dropped by half to less than 150,000 square feet of treated area with the introduction of cyantraniliprole, nithiazine, and imidacloprid bait products.

Cyfluthrin (Tempo)

This material is available as a dust, wettable powder, and a flowable form. Cyfluthrin has largely replaced many insecticides previously used for lesser mealworm control. Premise treatments are applied at a rate of 0.004 to 0.008 pound active ingredient per 1,000 square feet of surface area. Dust formulations (0.1 percent) are applied at 0.02 or 0.05 pound of active ingredient per 1,000 square feet of surface area.

lambda-cyhalothrin (Grenade)

This material is available as a wettable powder and microencapsulated concentrate. Used primarily for fly control in poultry houses, lambda-cyhalothrin is applied as a premise spray at a rate of 0.001 to 0.01 pound active ingredient per 1,000 square feet of surface area.

Permethrin (numerous trade names)

Available as a dust, wettable powder, and emulsifiable concentrate, permethrin is used on more than 10 percent of the birds (layers, breeders, pullets) treated for ectoparasites. Treatment is most often applied to birds at a rate of 1 gallon of spray (0.004 pound of active ingredient) per 100 birds. Premise application at the same concentration is made at a rate of 1 to 2 gallons spray per 1,000 square feet of surface area. Dust formulations (0.25 percent) are applied to birds (dust boxes) and premises (litter) at a rate of 1 pound (0.003 pound of active ingredient) per 100 birds or 10 pounds (0.03 pound of active ingredient) per 1,000 square feet of litter surface, respectively. Premise treatments for fly and beetle control are applied at a rate of 0.01 to 0.05 pound of active ingredient per 1,000 square feet of surface area. Space sprays for fly control are applied at approximately 0.001 to 0.006 pound of active ingredient per 1,000 cubic feet of volume.

Permethrin is applied to approximately 17 percent of area in North Carolina poultry houses (34.1 million square feet) to control a variety of pests. Resistance to permethrin is common.

Cypermethrin (Zetagard LBT)

Cypermethrin dust is available for lesser mealworm control in broilers. This material can be applied with a drop spreader at the rate of 50 pounds per flock prior to bird placement for a single treatment or 25 pounds per flock prior to placement and a second 25 pound treatment not less than three weeks before shipping.

Pyrethrins (numerous trade names)

Available primarily as an emulsifiable concentrate, these materials are used mainly as space sprays for fly control. About 6 million square feet of the area in North Carolina poultry houses (3 percent) are treated with pyrethrins. The insecticide (synergized with PBO) is generally applied at a rate of 0.0002 to 0.001 pound of active ingredient per 1,000 cubic feet of volume. It is used to treat 6 percent of breeders and layers for mites and lice at a rate of approximately 0.01 pound of active ingredient per 100 birds.

Orthoboric acid (Darkling Beetle Control)

Available primarily in dust formulations and used for the control of lesser mealworms, boric acid is applied at a rate of approximately 10 to 20 pounds active ingredient per 1,000 square feet of floor area. The material may also be applied as a spray at the same rate. The product is little used by producers largely due to its unpredictable efficacy.

Cyromazine (Larvadex, Flyzine, Neporex (Granular))

Available as a feed additive and soluble liquid, cyromazine is used for the control of flies in broiler breeders, layers, and pullets. The feed additive is administered at 0.01 pound of active ingredient per ton of feed for a period of four to eight weeks per treatment cycle. The liquid formulation is applied to manure beneath slats or cages at a rate of approximately 0.01 pound of active ingredient per 100 square feet.

Cyromazine is used for fly control with slightly more than 76 percent of breeders and layers each year, primarily at the start of a flock cycle when fly suppression is most difficult. More accurately, the material is used for only about four to eight weeks per flock cycle of 44 to 72 weeks. A granular formulation exists for controlling maggots in manure storage areas.

Nithiazine (QuikStrike)

Formulated as an insecticidal strip and used for fly control, nithiazine strips (1 percent) are hung in poultry buildings. The recommended placement density of 1 strip per 100 to 300 square feet is seldom used due to the size of production houses (12,000 to 36,000 square feet) and the cost per strip. Typical placement is one strip per 1,000 to 1,500 square feet.

Carbaryl (Sevin)

Label changes for carbaryl have rendered this insecticide irrelevant for poultry producers. All uses for on-bird application have been withdrawn. Restrictions limiting premise treatment to building exteriors makes the compound of little value for control of primary structural pests such as the lesser mealworm.

Imidacloprid (QuickBayt)

Available as a 0.5 percent bait, imidacloprid is used as a scatter bait (.002 pound active ingredient per 1,000 square feet). The product may also be mixed with water and applied to fly resting sites on walls as a paint-on. The bait has replaced the use of methomyl baits on approximately 150,000 square feet of poultry housing.

Esfenvalerate (FenvaStar EcoCap)

Available primarily as a 3.5 percent microencapsulated formulation, esfenvalerate is used infrequently for house fly and litter beetle control.

Cyantraniliprole (Zyrox, Cyanorox)

Available as a 0.5 percent bait, cyantraniliprole is used as a scatter bait (0.2 to 0.4 pound active ingredient per 1,000 square feet respectively for low or high house fly infestations). The product may also be applied in bait stations for indoor use. The bait is relatively new to the market, and provides an alternative mode of action for resistance management.

Current Insecticide and Miticide Recommendations for Poultry

You can find current NC State Extension recommendations for insecticide and miticide use on poultry (including information on formulations, application rates, and precautions/limitations) in Table 5-13E: Insect Control for Livestock and Poultry – Poultry from Chapter 5—Insect Control of the North Carolina Agricultural Chemicals Manual.

References and Resources

References

Arends, J. J. 1991. “External Parasites and Poultry Pests.” In Diseases of Poultry, 9th edition, ed. B. W. Calnek, H. J. Barnes, C. W. Beard, W. M. Reid, and H. W. Yoder Jr. Iowa State Univ. Press.

Arends, J. J., and S. M. Stringham. 1992. Poultry Pest Management. AG-474. N.C. Cooperative Extension.

Austic, R. E., and M. C. Nesheim. 1990. Poultry Production, (No. Ed. 13). Lea & Febiger.

Murillo, A. C., and B. A. Mullens. 2016. “Diversity and Prevalence of Ectoparasites on Backyard Chicken Flocks in California.” Journal of Medical Entomology, 53(3), pp.707-711.

National Agricultural Statistics Service, USDA. 2018.

National Agricultural Statistics Service, USDA. 2017.

North Carolina Poultry Federation 2018.

Parkhurst, C. R., and G. J. Mountney. 2012. Poultry Meat and Egg Production.

Sherrell, E. M. (ed.). 2004. North Carolina Agricultural Statistics 2004. Publication No. 204. North Carolina Department of Agriculture and Consumer Services.

Toth, S. J. Jr. 1996. A Survey of Pesticide Use on Poultry and Tomatoes in North Carolina. Part II: Poultry. Data report to the USDA National Agricultural Pesticide Impact Assessment Program. June 1996. N.C. Cooperative Extension.

Toth, S. J. Jr., S. M. Stringham, and D. W. Watson. 2002. Poultry Pesticide Use Survey in North Carolina. Data report submitted to the Southern Region Pesticide Impact Assessment Program, February 15, 2002. N.C. Cooperative Extension, Raleigh.

Resources

Insect Pests of Animals. VetPestX. S-1060 Multistate Project.

North Carolina Department of Agriculture and Consumer Services Pesticide Section. Pesticide Registrations

The Crop Profile/PMSP database, including this document, is supported by USDA NIFA.