Heat Stress in Laying Hens

Heat stress is one of the primary concerns for laying hen production in the summer as heat waves may significantly increase flock mortality and reduce egg production in hen houses. The use of mechanical ventilation and cooling cells are popular cooling methods used in the southern US, including Georgia. However, most of the layer farms in the US Midwest (where over 50% of US table eggs are produced) do not have evaporative cooling systems due primarily to lack of usage during the extended winter months. Evaporative cooling cells and foggers are common cooling methods used in broiler houses, but those methods may not be sufficient in cooling layers during the hot and humid weather, when the dry bulb temperature (air temperature measured with sensors) and wet bulb temperature (air temperature standardized at 100% relative humidity) tend to be closer in their measurement. Surface wetting (water sprinkling/spraying) is one method that has been proven effective to cool broiler chickens and reduce mortality in broiler and broiler breeder housing during hot and humid summer days. However, there is a lack of research on bird cooling through surface wetting for laying hens, especially within cage-free housing, the fastest growing egg production system in the US. This Extension article will introduce a sprinkler system tested for cooling cage-free laying hens.

Sprinkler System and Hen Body Surface Temperature Monitoring

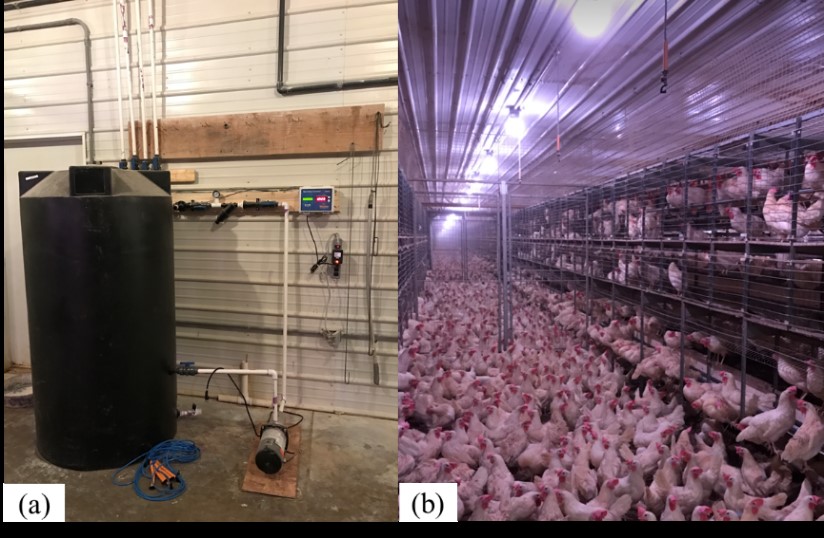

An experimental sprinkler system (Fig. 1) was installed and tested for summer cooling in a midwestern commercial aviary cage-free henhouse. The henhouse was populated with 50,000 DeKalb White hens and measured at 505 L × 70 W × 10 H ft).The body surface temperature of hens was monitored with thermal cameras for quantifying heat stress and relief efficiency. Two thermal cameras (FLIR T440, FLIR Systems Inc., Wilsonville, OR) were installed (Fig. 2) at a height of 6.6 ft above the litter floor to monitor variation of random hen surface body temperature before and after water sprinkling. The FLIR Tool, a program developed by the FLIR company (FLIR Systems Inc., Wilsonville, OR), was used to analyze the surface temperature of the hens.

Figure 1. The sprinkler system: (a) water spray control system and water storage tank – 200 gal.; (b) sprinklers installed above the litter floor at 6.6 ft high.

Water was sprinkled at the rate of 0.72 gal. per 1000 ft2 per 20 second intervals when the house air temperature was higher than 95oF. Due to the difference in the row widths, two types of sprinklers were installed. Bow-tie sprinklers (DAN-blue-180° nozzle, 43 L h-1 rated output at 276 kPa, Maasdijk, The Netherlands) were installed for the narrow sidewalk (4 ft wide) rows. Spiral sprinklers were installed (DAN-orange-360° nozzle, 35 L h-1 rated output at 276 kPa, Maasdijk, The Netherlands) in the two wider middle (9.2 ft) rows. The farm utilized well water for the production houses. The well water had a low temperature (e.g., 50°F), therefore, it was not sprayed directly on the birds due to animal health concerns. A tank (black tank with volume of 200 gal. in Figure 1-a) was designed for storing the well water and raising the temperature of the water to 70-75°F, which is within the comfort temperature zone for laying hens.

Figure 2. Thermal cameras setup above litter floor in the cage-free house.

Heat Stress Relief Efficiency

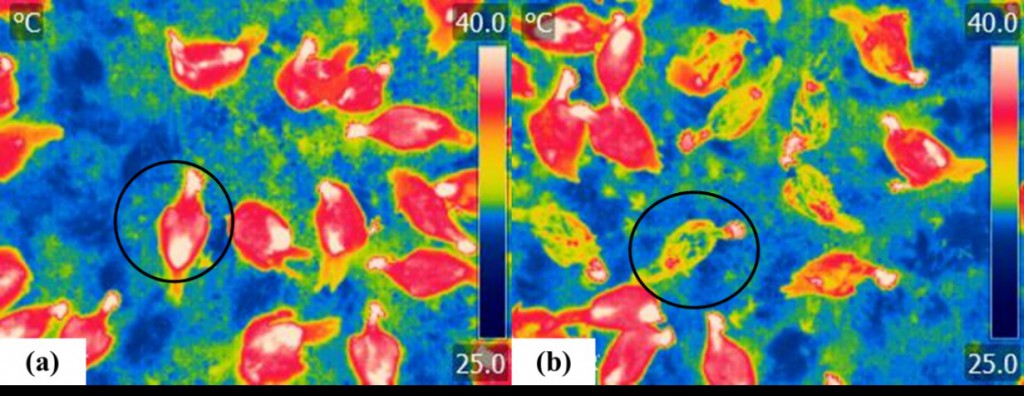

Figure 3 shows the thermal images taken before and after a 20 sec. water spray event when indoor air temperature was approximately 95oF with 40% relative humidity. Before spraying, hen body surface (back) corresponded to high surface temperature in the IR thermograph scale (fig. 3-a). The white area on back and head of the hens represents areas of no feather coverage. During or immediately after spray (fig. 3-b), the wetted birds showed up green or blue in the color range due to reduced body surface temperature.

Figure 3. Thermal images (25 ~ 40 oC = 77 ~ 104 oF) of laying hens before and after sprinkler cooling (a) 15 sec before spray; (b) 15 sec after spray. The hen that is circled was the same individual within the two photos.

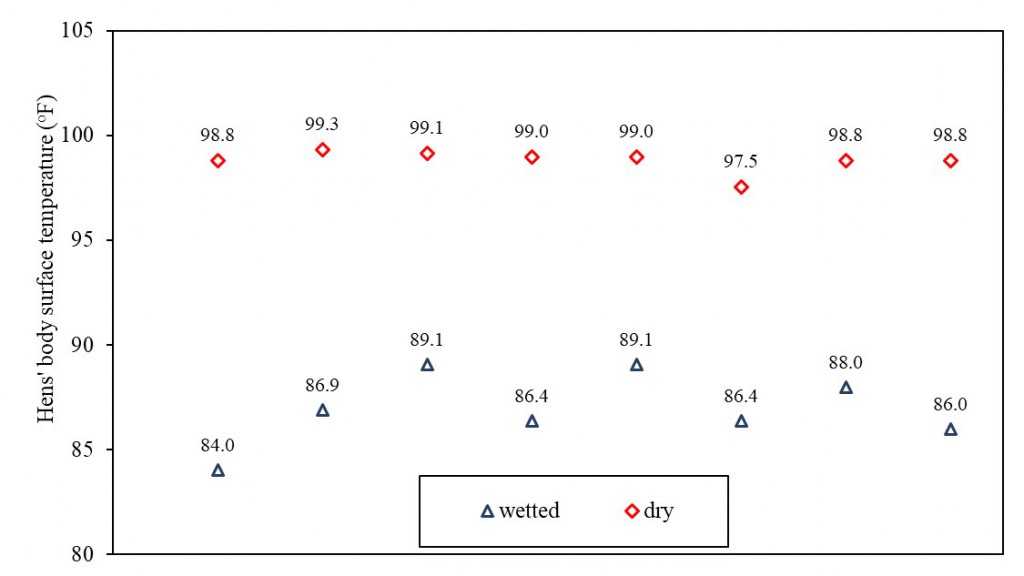

For assessing body surface temperature, thermal images before spray and 20 seconds afterward were selected for quantifying surface temperature (Figure 4). Before sprinkling, the body surface temperature of birds was 99±0.4 oF, which was reduced to 87±1.7 oF after water sprinkling. The cooling effect was about 12 oF on average immediately after water sprinkling. The body surface (back) temperature of wetted hens was still 9 oF cooler than dry hens after 3 minutes. The cooling effect for some birds lasted up to 10 minutes, though most were dry within 10 minutes according to thermal images. Due to the potential for wetting the bedding material, it is suggested to spray water at 20-30-minute intervals. The sprinkler system treated the floor area only and not in or beneath the aviary system.

Figure 4. Body surface temperature analysis based on randomly selected birds before and after sprinkling.

Researchers at Iowa State University have proved that the sprinkling cooling could improve egg production by up to 5.6% and reduce mortality by over 20% in summer. The sprinkler system is different from evaporative cooling pads and fogging systems. The sprinkling method has larger water droplets and will cool the animals directly. The cool cell and fogging systems are indirect cooling method as they are intended to cool the air versus the birds directly. Therefore, the sprinkling method has less water usage potential than the other two methods. Researchers at the University of Arkansas have conducted related analysis and concluded that sprinkler cooling systems could save over 50% water usage with a similar cooling effect compared to other fogging systems. Besides cage-free laying hen houses, the sprinkling system may also be considered in free range production systems or backyard flocks as the evaporation cooling pads are not applicable in open area or natural ventilation facility.

Cautions should be taken for appropriate and timely maintenance of the sprinkler system. Piling behavior was observed for birds beneath a sprinkler with continuous dripping. Another concern for sprinkler systems is increased litter moisture as the sprinkling can wet not only birds on the floor but also the bedding material. Sprinkling dosage and intermediate timing between spray events are critical factors to consider for improving cooling efficiency and the overall house environment. Further studies should be conducted to optimize sprinkling operation (e.g., water temperature adjustment, dosage, and intermediate time in different housing systems) and evaluate the variation of hens’ core body temperature and long-term effect on egg production in a commercial cage-free houses or free-range house. This writing discussed laying hen cooling only. More information about broiler cooling can be found at UGA Poultry Housing Extension website: https://www.poultryventilation.com/.

Summary

Surface wetting has proven effective to cool birds and reduce mortality in poultry production. A cage-free hen house case study showed that sprinkled hens had up to 12 oF lower body surface temperature than non-sprinkled ones immediately after a 20-second spray event. The sprinkled hens were still 9 oF cooler than the non-sprinkled ones 3 minutes afterward. The cooling effect for some birds lasted for up to 10 minutes, though most would dry out soon under the testing conditions (temperature of 95 oF and relative humidity of 40%). It has been reported that sprinkler cooling could save over 50% water compared to similar cooling efforts. However, cautions should be taken to prevent system leaks and the creation of wet bedding.

Source: Dr. Lilong Chai, UGA Poultry Engineering Specialist: UGA Department of Poultry Science Extension